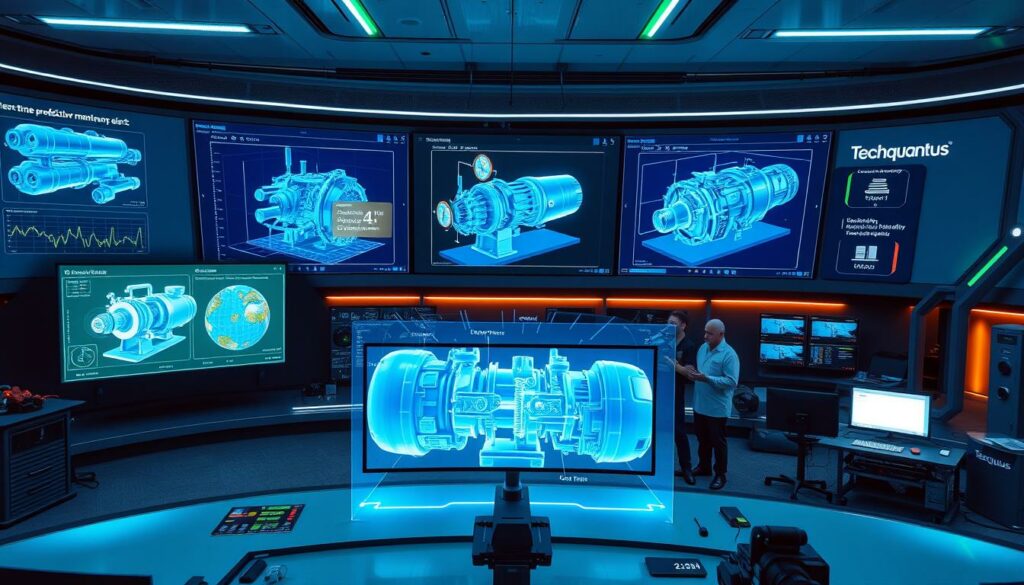

By 2025, over 50 billion devices will connect to the Internet of Things (IoT), changing how we do predictive maintenance. This growth has made digital twin technology more important. It creates exact copies of real assets for better analytics and maintenance plans.

In 2024, companies see how Digital Twins are key for better predictive maintenance. This leads to more efficiency, less downtime, and better performance.

Digital twin technology lets companies see how their assets work in real-time. This gives them insights into possible failures before they occur. Predictive maintenance with these simulations can save money and make equipment last longer. This tech boost not only makes things more reliable but also boosts productivity. For more on this new approach, check out this insightful resource on 3D object detection and sensor fusion.

Key Takeaways

- Over 50 billion devices are expected to be connected to the IoT by 2025, significantly influencing predictive maintenance.

- Digital twin technology allows for real-time simulation of assets, enhancing predictive maintenance strategies.

- Implementing Digital Twins helps businesses reduce costs and extend equipment lifespans.

- Operational efficiency increases with the enhanced analytics provided by digital twin technology.

- Understanding the impact of digital twin simulations on equipment reliability is crucial for manufacturing success.

Introduction to Digital Twins and Predictive Maintenance

Digital Twins change how we handle predictive maintenance and boost efficiency. They are digital copies of real assets, using live data to check and analyze how they work. This tech lets companies predict when equipment might break down, cutting down on unexpected stops and saving on maintenance costs.

Creating a Digital Twin has its hurdles. It’s key to make sure the digital model matches the real asset’s parts and setup. In the design stage, “As-is and as-built” methods help keep the digital and real worlds in sync. This focus on accuracy means better data and insights on performance.

There are still hurdles in making Digital Twins work, like missing digital parts or poor documentation. Yet, many sectors, from manufacturing to cars, see the value in Digital Twins. Learning to blend them into maintenance plans is key to success.

By focusing on making things run better and keeping an eye on performance, companies can see big gains. For more tips on improving your digital strategy, check out more on ethical AI. Using Model-Based Systems Engineering (MBSE) helps in planning system architecture. This method is vital for building models that work well together, essential for Digital Twins.

Understanding Digital Twin Technology

Digital twin technology has changed how industries handle data and check system performance. It connects the physical and digital worlds by making exact virtual copies of real objects. Knowing what digital twins are and their parts is key to using them well.

Definition of Digital Twins

The definition of digital twins is more than just copying real things. It mixes real-time data and analytics to watch, manage, and forecast how these things work. Companies use digital twins to see how things perform, make processes better, and spot problems early.

Components of Digital Twin Technology

Several important components of digital twins make them work:

- Real-time Data Interfaces: These help talk between the real and digital sides.

- Advanced Simulation Capabilities: These tools let you test things virtually, showing how they might act in different situations.

- Machine Learning Algorithms: These algorithms help predict things, letting companies make smart choices with data.

- Hierarchical Structures: In Model-Based Systems Engineering (MBSE), these structures help manage complex systems.

- Influence Matrices: These matrices show how different parts affect each other, giving a full view of the system.

Using these parts makes digital twins work well, leading to new ideas and better work in areas like making things and healthcare. Research is ongoing to make digital copies for old industrial objects, as seen in studies from the International Council on Systems Engineering (INCOSE).

The Role of Digital Twins in Industry 4.0

Digital Twin technology is key in Industry 4.0, making things more efficient and innovative. It makes virtual copies of real assets, letting companies check, test, and analyze data easily. When IoT meets Digital Twin, it connects the real and digital worlds. This helps make quick decisions and predict when things might break.

Integrating IoT with Digital Twin Technology

Combining IoT devices with Digital Twin tech creates a strong way to handle data. Sensors on machines send data to the virtual model, tracking how well they work. This setup makes things run smoother and opens up new chances for smart analysis. It helps cut down on downtime and boosts productivity.

Benefits of Digital Twins in Smart Manufacturing

Using Digital Twin tech brings big wins in smart manufacturing. Here are some main benefits:

- Enhanced Efficiency: Real-time insights help make better decisions and streamline operations.

- Waste Reduction: Predictive analytics spot problems early, cutting down on waste.

- Quicker Production Cycles: Quick simulations and tweaks mean faster production times.

Looking into Industry 4.0, consider the carbon fiber-reinforced polymer planing head in woodworking. It shows how new materials and tech can make manufacturing better. For more on its design and big impact on productivity, check out the future of manufacturing innovation.

How Digital Twins Enhance Predictive Maintenance

Digital twins are key to better predictive maintenance. They let you watch over assets in real-time, giving you important data. This data helps you spot trends and possible failures early. This way, you can make your equipment more reliable and make it last longer.

Real-time Monitoring and Data Analysis

Real-time monitoring is at the heart of predictive maintenance. Digital twins copy the real world, letting you see how machines work in a virtual space. They collect data non-stop and analyze it quickly. This helps spot problems or wear early. It keeps you updated on your assets’ health.

Asset Performance Optimization

Improving how assets work is key to saving money and boosting efficiency. With real-time data, companies can fix things before they break down. Digital twins help plan maintenance better and use resources wisely. This leads to better performance and lower costs in fields like battery management and aerospace.

Studies show using digital twins can make things up to 30% more efficient. This shows how big an impact these technologies have on predictive maintenance.

| Indicators | Before Digital Twin | After Digital Twin |

|---|---|---|

| Maintenance Costs | High | Reduced by 30% to 80% |

| Development Cycle | 36-60 months | 9-15 months |

| Asset Lifespan | Standard | Extended by 60% |

| Performance Improvements | N/A | 46% Increase |

As digital twin tech grows, so will predictive maintenance. Staying ahead means using this new tech to improve how you manage assets. For more on the future of robotics, check out this resource.

Key Advantages of Using Digital Twins for Predictive Maintenance

Using digital twins in predictive maintenance has many benefits. This tech helps cut costs and boost efficiency, making your equipment last longer. It uses real-time data and advanced models to make your operations smoother and less prone to downtime.

Cost Reduction and Efficiency Improvements

Digital twins lead to big cost reductions by fixing problems early. For example, industries using them have cut production costs by up to 35%. They also help reduce mistakes and speed up development, making things more efficient.

Traditional development times can go from 36–60 months to just 9–15 months with this tech. This means faster and better results.

Increased Equipment Lifespan

Digital twins help extend the life of your equipment by improving maintenance. They let you check on your assets in real-time, so you can fix issues before they get worse. This can increase battery life by 60% and cut lifetime costs by 30%.

With these improvements, your machines and equipment work longer, saving resources.

For more info on how to use Model-Based Systems Engineering (MBSE) and system architecture with digital twins, check out this resource. It shows how digital twins are key to better predictive maintenance.

Implementing Digital Twins in Industrial Settings

Starting with digital twins in industrial settings needs a clear plan. You must follow key steps to make the most of digital twin technology. This can greatly improve your operations.

Steps to Deploy Digital Twin Technology

First, look at your current setup and see how digital twins can help meet your goals. Important steps include:

- Assess your existing systems and processes to see where digital twins can fit in.

- Make a detailed plan with goals, budget, and timeline for using digital twins.

- Pick the best platforms and tools for your digital twin to work well and share data in real-time.

- Get everyone on board to ensure support and teamwork during the setup.

Choosing the Right Simulation Software

Choosing the right simulation software is key to a successful digital twin setup. Good software should model accurately and offer strong data analytics. Think about these points:

- Make sure it works well with your current systems for easy data sharing.

- It should allow for real-time simulations to analyze how things work.

- The interface should be easy for your team to use.

- The company behind the software should offer strong support and updates.

For more tips on a successful digital twin setup, see this guide on securing your digital world.

| Factor | Importance | Consideration |

|---|---|---|

| System Compatibility | High | Must integrate smoothly with what you already have |

| Real-time Simulation | Very High | Key for checking how things perform |

| User Interface | Moderate | Needs to be easy for everyone to use |

| Support and Updates | High | Important for keeping the tech up-to-date |

Challenges in Adopting Digital Twins for Predictive Maintenance

Using digital twins in predictive maintenance has its hurdles. These challenges start with managing and integrating data into current systems. Companies face both technical and cultural obstacles to switch from old methods.

Data Management and Integration Issues

Good data management is key for digital twins to work well. This tech needs lots of data for real-time checks. But, it can run into problems like:

- Data silos that make it hard to get to important info

- Issues with different software and hardware working together

- The need to make data flow smoothly across various platforms

These problems can make digital twins and real assets not work well together. This leads to poor performance and higher costs. To fix this, companies need strong plans and tools for easy integration.

Overcoming Resistance to Change

Changing to digital twin tech is also about how a company works. Workers might not want to change because of:

- Worries about losing their jobs as automation grows

- Not knowing how digital twins help

- Not getting enough training on new ways and tech

To beat this, companies should focus on good change management. This means offering thorough training and showing how digital twins can improve operations and jobs.

Case Studies of Successful Digital Twin Applications

Looking into digital twin success stories shows how this tech changes the game in many fields. We see big leaps in battery making and aerospace upkeep, thanks to digital twins. These tools have changed how things work for the better.

Battery Manufacturing Examples

In battery making, digital twins bring big wins. They can cut costs by up to 80%, shortening development time from 36-60 months to just 9-15 months. This means new tech hits the market faster.

Companies using digital twins for batteries see big gains. For example:

- A 46% boost in cell performance.

- A 60% jump in battery life.

- A 30% cut in costs over the battery’s life.

The GigaFactory Nevada shows how big digital twins can be, making about 1.7 billion cells a year. This leads to lower costs and better monitoring, cutting emissions by 50% per project.

Aerospace Maintenance Applications

In aerospace, digital twins change how we do maintenance. They help keep planes reliable and reduce downtime. By mimicking real aircraft parts, they spot problems early.

This early warning lets maintenance teams plan ahead, keeping planes ready to fly. Digital twins are key to managing aircraft parts from start to finish.

Using tools like Model-Based Systems Engineering (MBSE) makes these digital twins even better. They help keep the digital and real worlds in sync. This is vital for today’s flying machines.

For more on making great digital twins, check out this detailed study.

The Future of Digital Twins and Predictive Maintenance in 2024

As 2024 approaches, digital twins in predictive maintenance are changing fast. Expect to see more AI and IoT in action. These changes will make things run smoother, give better data, and predict problems better in many fields. Companies that keep up will get ahead, using real-time monitoring and predictive analysis easily.

Emerging Trends and Technologies

The future of digital twins looks bright, especially for industries like battery making. Costs could drop by 80% and development times get shorter. With tools like TOGAF and MBSE, companies can use digital twins to improve and innovate fast. This means big chances for new investments in digital twin tech, leading to better asset care and maintenance.

Investment Opportunities in Digital Twin Solutions

Leaders in the industry are coming together, like the Global Battery Alliance, offering big investment chances. Using digital twins, companies can boost performance by 46% and extend battery life by 60%. This shows why investing in digital twins is key for better maintenance and sustainability. For more on how system architecture plays a part, check out this study.

FAQ

What are Digital Twins and how do they work?

Digital Twins are like virtual copies of real-world objects. They use real-time data for monitoring and analysis. This helps companies make better decisions and work more efficiently.

How do Digital Twins contribute to predictive maintenance?

Digital Twins predict when equipment might break down. They look at performance data and spot trends. This helps plan maintenance ahead, cutting down on unexpected downtime and costs.

What are the key components of Digital Twin technology?

The main parts include real-time data interfaces, advanced simulations, and machine-learning algorithms. These help make smart decisions and predict performance.

How do Digital Twins integrate with IoT devices?

Digital Twins work well with IoT devices. They collect real-time data and improve operations. This helps with predictive maintenance and makes things more efficient.

What benefits do Digital Twins provide in smart manufacturing?

In smart manufacturing, Digital Twins make things run smoother. They offer real-time insights, cut waste, and speed up production. This boosts productivity and reliability.

What steps are needed to implement Digital Twin technology?

To get started, you need to check your current setup, plan carefully, and pick the right software. This includes choosing simulation software to model and analyze your systems.

What are the main challenges in adopting Digital Twins?

Challenges include managing data, fitting with current systems, and getting people to change. Having good plans for change helps overcome these issues.

Can you give examples of successful Digital Twin applications?

Sure, there are success stories in battery making and aerospace maintenance. These show big cost cuts and better efficiency thanks to Digital Twins.

What are the emerging trends in Digital Twin technology for 2024?

Trends include more AI, wider use of IoT, and big investments in Digital Twins. These will push forward industrial operations.

Source Links

1 . https://www.rtinsights.com/why-real-time-businesses-need-flight-data-recorders/

2 . https://ventsmagazine.com/2024/09/08/cnc-machines-vs-turret-lathes-which-options-should-you-go-for/

3 . https://www.mdpi.com/2079-8954/12/9/355

4 . https://www.technologynetworks.com/tn/blog/digital-twin-technology-drives-major-improvements-in-battery-efficiency-and-cost-390615

- Budgeting and Cost Control for IT Projects: My Expert Advice

- Learn How to Manage IT Projects Effectively with My Advice

- I Share My Best Data Backup Strategies Using Cloud Storage

- I Learned About AI Mistakes That Could Change Your Life

- Sustainable & Green Energy Solutions for Next‑Gen Data Centers Trend Report

Related posts:

How Robotics is Revolutionizing the Manufacturing Industry

How Robotics is Revolutionizing the Manufacturing Industry

How to Leverage Hyperautomation for Streamlining Operations

How to Leverage Hyperautomation for Streamlining Operations

How to Implement Robotics for Business Process Automation

How to Implement Robotics for Business Process Automation

How to Transition to Serverless Computing in 2024

How to Transition to Serverless Computing in 2024

How 5G is Transforming IT Infrastructure and Services

How 5G is Transforming IT Infrastructure and Services

The Future of IT: Predictions for the Next Decade

The Future of IT: Predictions for the Next Decade